In the large ongoing transition towards a low-carbon society, bioenergy is an essential part of the new emerging bioeconomy needed to meet several of the sustainable development goals.

In this transition, the bioenergy sector has the potential to produces, among other things, heat, electricity, biochar, and synthetic natural gas (SNG) using sustainable and renewable resources or feedstocks from biomass, such as wood residues, agricultural crops, forest residues, and organic waste. Managing the supply chain for these feedstocks involves multiple activities including biomass sourcing, transportation, processing, production, and distribution. This give rise to complex challenges in evaluating profitability, increasing performance, and managing integrated planning. The challenges include handling processes, coordination of multiple assortments and different value chains, for example, forest and agriculture. The supply chains are difficult to integrate due to the difference in assortment attributes, conversions, and processes. Optimization tools and decision support systems (DSS) are important for ensuring the efficiency of the supply chain by integrating all stages and thus, reducing costs, increasing profitability, and ensuring due diligence. The results offer a reduction in waste, better supply balancing and improvement of the sustainability using multiple different biomass feedstocks at a lower cost. Combining forest, agro and waste streams in a more integrated approach to help deliver the right biomass, in the right form, to the right customer at the right time is important when assessing future smart and efficient biomass mobilization and logistics.

Development of Bioflow

We have developed an approach to integrate the supply chain and utilize decision support systems for planning feedstocks as well as analyzing market viability and profitability for investment and development of SNG and energy production. In more detail, we have developed a generic optimization model and a robust methodology. We are using this approach to analyze data to assess the potential for biomass production at regional, national, and international levels. The developed tool can incorporate a range of data, such as different feedstocks, multiple industrial partners, transportation availability and capacity, different seasonal variability of the feedstocks, and capacity needs to identify supply areas with the highest potential for biomass production.

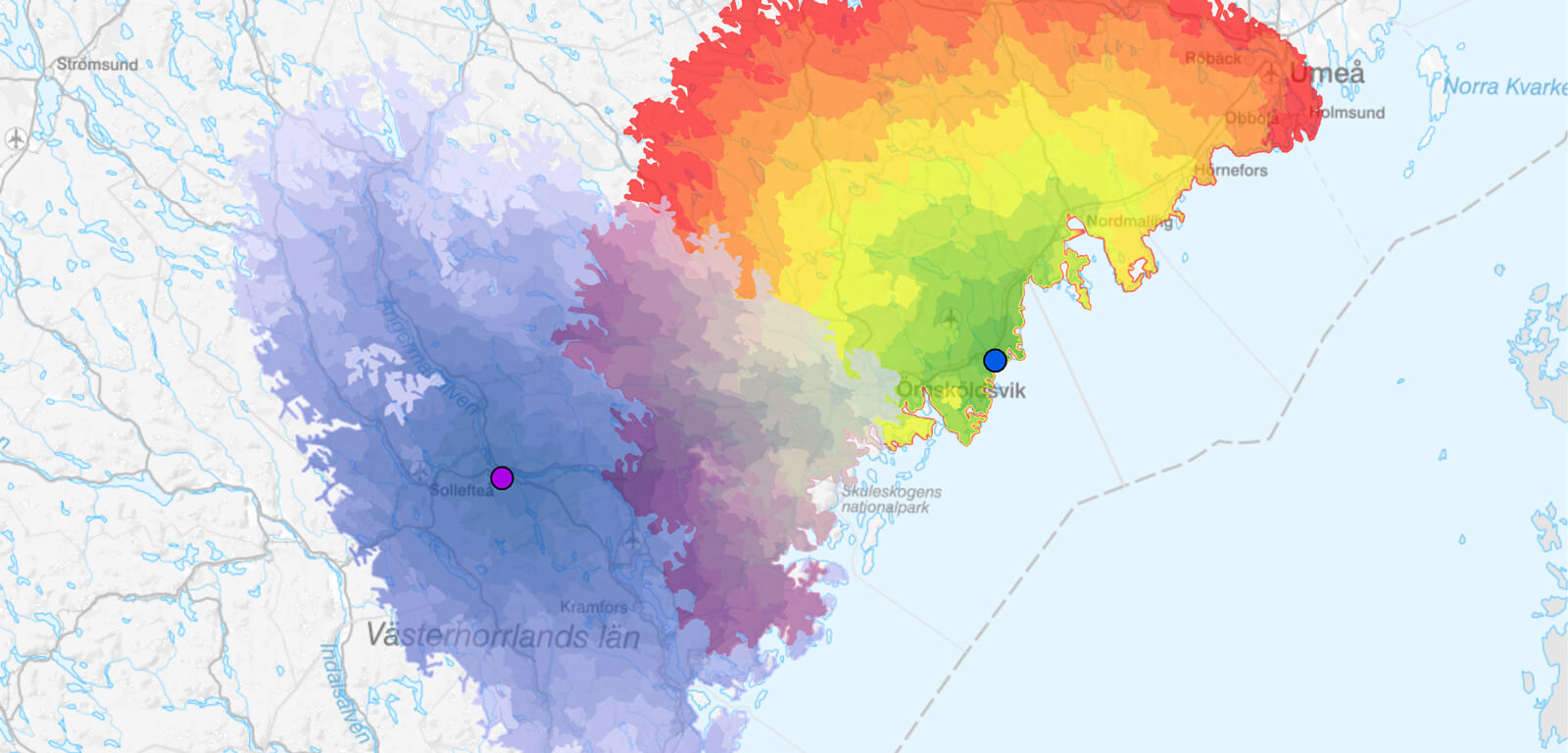

Utilizing Bioflow as an optimization model for planning feedstocks, including timber, pulp, and forest residues. The developed model includes possibilities for collaboration among partners, complex processes, general assortment attributes and cost functions for all stages of the supply chain. Based on Woodflow, used by several large forest companies in Sweden including SCA, Södra, and Stora Enso. Bioflow considers factors such as distance, mode of transport, storage, processes, and handling requirements to determine the most efficient and cost-effective transport and logistics solutions. One key element of Bioflow is an integrated distance calculator which based on local road network information calculates accurate distances with very high resolution and efficiency. The system is flexible and efficient in using optimization for modelling the supply chain. As part of the development of the method for bioenergy, this has been incorporated into the Horizon 2020 project FlexSNG. It enables adaptations to meet the needs and challenges of the bioenergy supply chain, including the essential steps for SNG production. Bioflow is also used in the bioenergy sector handling sales and seasonal planning for forest residues. The toolset is adapted for EU countries and Canada utilizing data sources for resource availability and road networks.

Several factors have influenced the development of a tailored and integrated supply chain model. The analyses and ongoing work have identified that smart use of the seasonal variations, geographical availability, and quality have the potential to contribute to lower supply costs. The following cost reduction concepts were identified and available in the decision support system:

• Co-handling and transport

• Central storage nodes and terminals

• Sharing of resources, machines, and equipment

• Complementary effects and synergies with other systems

• Mixing different feedstocks to address quality challenges in production.

• Using different feedstock recipes throughout the year accounting for seasonal variation

• Information and coordination in the value chain

The DSS provides detailed resource maps for information about biomass resources, including their location, quantity, and quality. Moreover, it is used for different planning scenarios. Results from the system can be used to improve the basis for case studies, due diligence, and the development of future bioenergy production, creating input data for policy decisions and supporting the development of biomass-based industries.