The word optimize is often used as a general comment without any more detailed meaning on what is being done. For example, it is very easy to say that the route, the design, or the plan is optimized without any type of quantification. Most often, what is meant in practice is to do something as good as possible. In many applications, it is possible to manually find acceptable solutions to a problem.

The human brain works quite well to solve with, at least when the problems are relatively simple, and the number of possible solutions is not too many. To find good solutions is more difficult as it requires a good understanding of both the problem and the possible solutions. For this to happen there is a need for highly qualified staff members or professionals. To find the optimal solution is simply not possible even for such persons due to the high complexity or the number of potential solutions. This became evident during the second world war when quantitative models and methods began being developed to solve large logistics problems. Thie is where the word Operations Research (OR) was founded.

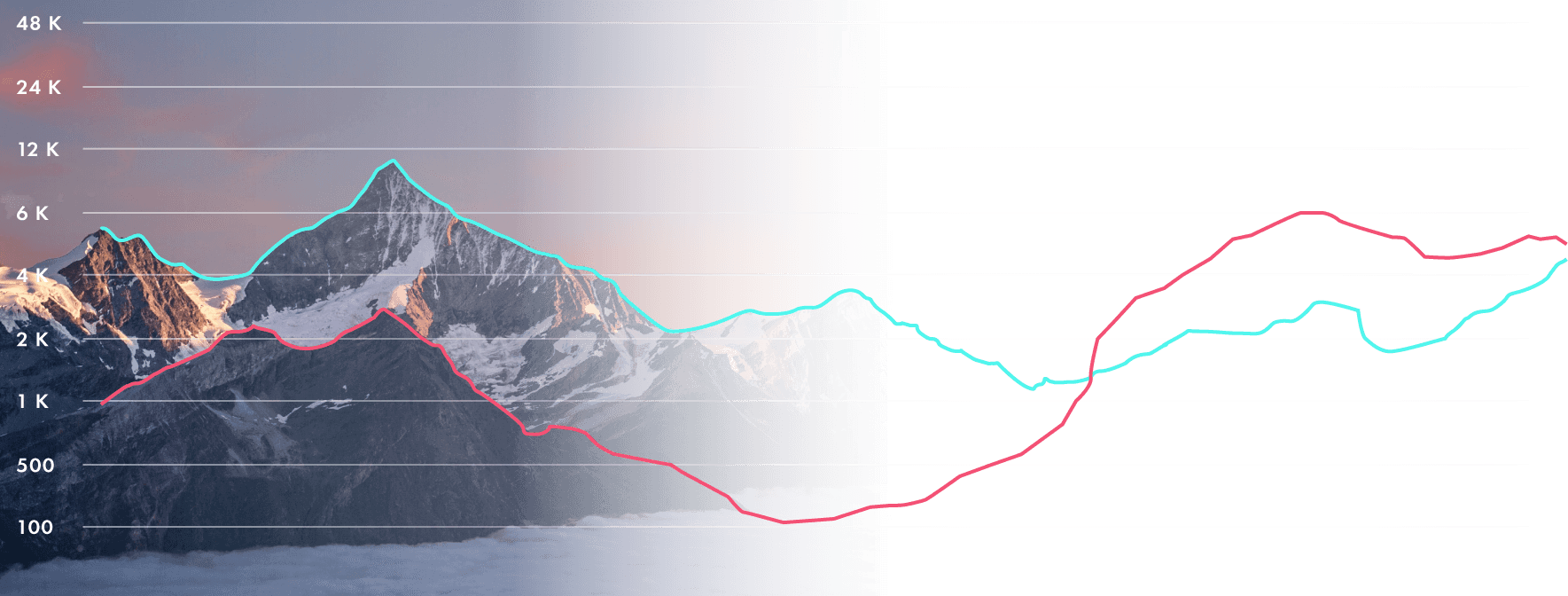

Optimization is closely related to OR, which comprises several science areas such as statistics, queuing theory, simulation, control theory, and production economics. Each of these is based on a quantitative/mathematical analysis for the decision making. Another related field is Mathematical Programming where the word ”programming” that also appears in the concept ”linear programming” originates from the English word program and also means planning. Other terms used to characterize operational researchers have evolved over the past 50 years. Often, “Management Science” (MS) was coupled with OR during the 1970s and 1980s. In the 2010s, the US INFORMS society adopted “Analytics”, defining it as “the scientific process of transforming data into insights for the purpose of making better decisions” (informs.org) and used the term to describe OR in the traditional context. Analytics is often separated into four different stages each used answering a related question: descriptive (what happened?), diagnostic (why did it happen?), predictive (what will happen?), and prescriptive (how can we make it happen?), each depending on the level of difficulty and value for the users.

Value chain management optimization

There are many applications where optimization can be used. To provide a general description, we can study a supply chain (SC) or a value chain (VC) that refers to the system and resources required to move a product or service from supplier to customer. The value chain concept builds on this to also consider the way value is added along the chain, both to the product / service and the actors involved. A value chain may have many companies and organisations involved. Value Chain Management (VCM) is a way for a company to optimize all the activities in its manufacturing process, from the design of the product to its delivery to the customer. VCM can help a company increase its efficiency, quality, and profitability by identifying and improving the value-added steps in each stage of the production process. VCM also involves coordinating and communicating with the suppliers, distributors, and customers to ensure a smooth and satisfying experience for all parties. There are many problems arising in the VC, for example, purchasing, transportation, production, distribution and sales. They appear for different planning horizons ranging from long term strategic planning (e.g. 5-30 years) down to operational planning where the planning periods may be as short as part of seconds. Depending on the problem studied there are specific requirement on the data required.

Finding the optimal solution

There is a standard process to be able to find an optimal solution to a problem. Given the real problem, we first identify its location and how it connects to other related problems. Also, there is a need to understand how it relates to longer term and shorter-term planning. Moreover, it is also important to analyze what data and information that are available. This analysis will provide a simplified formulation with assumptions and conditions on how the problem is coordinated and/or restricted. Next, we formulate the identified problem into a quantitative optimization model. This model consists of three main parts. The first is the decision variables which describes what is possible to vary in the problem. The second is the objective function which describes the goal or aim of the problem. The third is the part are the constraints that restricts the decision variables and provides the boundary conditions. There are many different models, and they are typically categorized into the groups linear, nonlinear and integer models. The easiest and most known is Linear Programming models where all variables are continuous. For such there are very efficient methods based on the well-known Simplex method developed by George Dantzig 1947. Integer variables with discrete values also includes so-called binary 0/1 variables which are used to denote logical decisions (yes/no variables). There are several main methods and the main are based on Branch and Bound methods. Such methods may take much longer time to solve and non-practical for practical use. Hence, many heuristic methods, developed for special purpose applications, give no guarantee of solution quality but is often very fast to solve. For nonlinear models there are also many methods, but the size of the problem is often limited to solve. Once the model is defined, we select a suitable method to solve the model. Depending on the type of model, there are many methods available. The selection depends on the model size, solution time available and solution quality required. Once a solution is found, it is critical to evaluate the results and if it is a solution to the problem first considered. Often, there is a need to add more decision variables or constraints to best describe the problem.

Important to note is the development of commercial modeling languages and fast solvers. The modeling languages, e.g. AMPL, LINGO and GAMS, combines a general mathematical model with a data instance and create input files for solvers. Today there exist many commercial solvers, e.g. cplex, minos, and gurobi, that efficiently can solve large instances.

To read more: Reference [1] is a textbook aimed for industrial engineering, mathematics, logistics and general engineering students at university level that describes optimization models and methods used for many industrial applications. Reference [2] is a Swedish version of [1]. Reference [3] gives a description of typical challenges in the optimization process.

[1] J. Lundgren, M. Rönnqvist and P. Värbrand, Optimization, Studentlitteratur, Sweden, 537 pages, 2010. (in English), ISBN: 978-91-44-05308-0

[2] J. Lundgren, M. Rönnqvist and P. Värbrand, Optimeringslära, Studentlitteratur, Sweden, 537 pages, 2010. (in Swedish), ISBN: 9789144053141

[3] M. Rönnqvist, OR challenges and experiences from solving industrial applications, International Transactions of Operations Research, Vol 19, No. 1-2, 227-251, 2012.